Week of 10/09/2017 - Progress Report 1

- Tamara Jovanovic

- Oct 13, 2017

- 3 min read

Topics covered: Getting familiarized with the Yokogawa AQ6370D Spectrometer and its features, Hardware Set Up Representation, Collimator, Fiber and Numerical Aperture Research

The Yokogawa AQ6370D Spectrometer is the latest iteration of high precision spectrometers from Yokogawa. The wavelength range varies from 600 nm to 1700 nm, and this will provide high accuracy readings once the team starts testing samples of glucose in different solutions. On this model of the spectrometer, both single mode and multi-mode fibers can be connected for testing, making this spectrometer very versatile and useful. For the purposes of out project, we will be using single mode fiber.

The spectrometer has a wide range of readings. In order to familiarize myself with the device, I went into the lab and tested dummy data. I connected the laser source from the spectrometer into the output of it, using single mode fiber. The spectrometer requires a wavelength calibration to be performed before the measurements are taken, in order to meet its specifications and guarantee accuracy. Since I was using built in components, wavelength calibration was set to the default, built-in measurement. The waveform I was getting looked as presented in Figure 1. This waveform started at 840 nm and stopped at 1670, which is almost the entire range of the spectrometer.

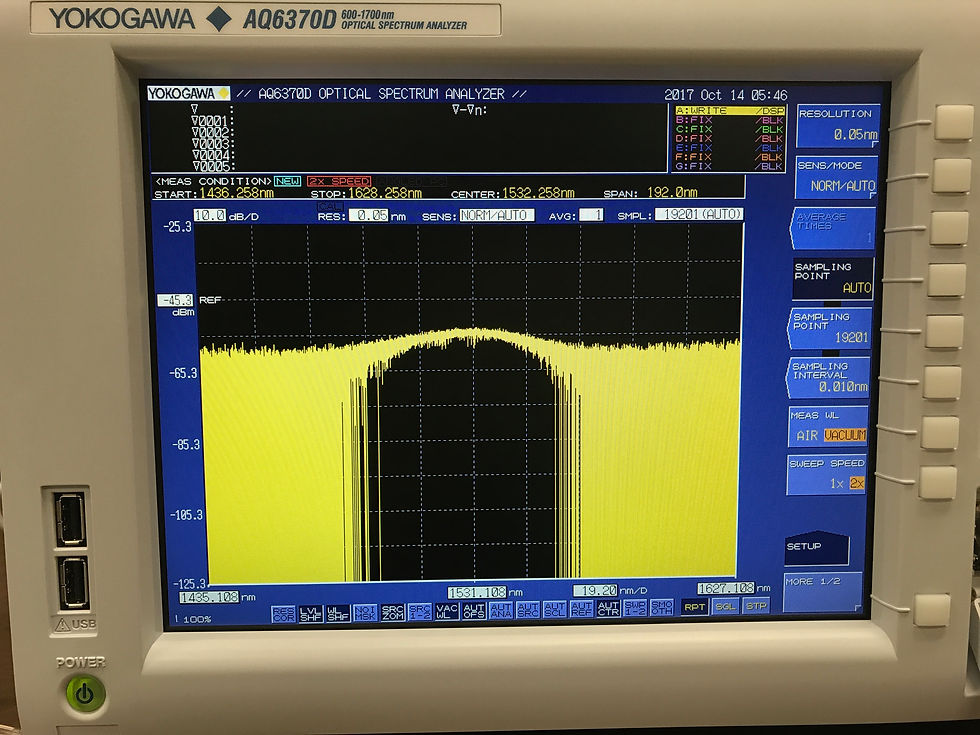

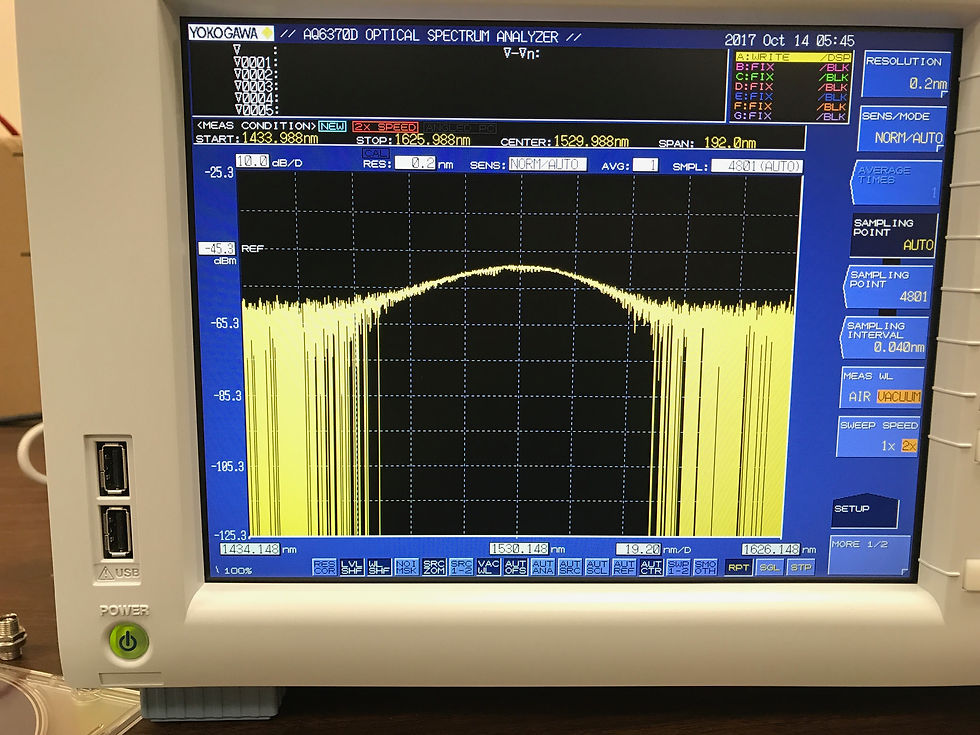

However, I wanted to make sure I can manipulate the spectrometer by zooming in at a specific wavelength, and setting it at the highest resolution. I set the reading close to about 1500 nm, just to watch what happens at that specific wavelength, since that is close to the wavelength of the laser we will be using for the experiment. The resolution readings offered by the spectrometer are as follows:

0.02 nm

0.05 nm

0.1 nm

0.2 nm

0.5 nm

The waveforms are represented in pictures below, chronologically, as listed above, according to resolution.

By observing these images of the various waveforms, it is safe to say that the most precise resolution reading will occur at 0.02nm, or if I’m being most accurate 0.018nm. This gives the cleanest waveform. In case of the glucose testing, this resolution feature will be very useful to us, as we will be able to read output waveforms of glucose in the most accurate manner.

The budget and components are still being finalized at this moment by The Team. After the components are ordered and delivered, the hardware will immediately start to be set up, and interfaced with. Until that happens, here’s a drawn schematic of what the hardware set up will look like.

The schematic includes a laser, 2 single mode fibers, 2 collimators, a cuvette on a stand with a solution in it with glucose and a spectrometer. The laser will emit a light, and though laser light is coherent and can stay focused at vast distances, we need to make sure that the light emitted doesn’t diverge or converge. Because of that, a single mode fiber will be connected out of the laser and into a collimator, in order to focus the light on our specific target, which is a cuvette. In order to capture the light coming out of the cuvette, a second collimator will be used, as well as a second single mode fiber, which will further be connected into the spectrometer for measurement readings.

When selecting a collimator and fiber, we need to make sure that the numerical aperture of the collimator matches the numerical aperture of the fiber or source. Numerical aperture (NA) represents the angle accepted or emitted by the light. If the NA of the source is greater than the NA of the optic, the optic is considered overfilled, and not all light will be collected by the light.

If the NA of the source is smaller than the NA of the optic, the optic is considered underfilled. In this case, all the light will be collected, but it will not span over the entire clear aperture of the optic.

This is why we need to be very careful when it comes to selecting components for this project. We want to be cost effective, and also accurate, and that requires having all the right components.

For next week, the components that need to be purchased should all be finalized, in order to receive them as soon as possible so that this project can achieve its milestones. Also, the hardware and software teams should start interfacing so that everyone can become familiarized with the procedures of setting up the equipment for testing.

Comments